A few times the head unit went off but I couldn't be bothered by it as my mind set was "belting wet, must have slipped" but that issue didn't really went off my head till I consulted my fellow friends, the Lutong Drag Crew on symptoms of a faulty alternator. They told me what are the symptoms they've experienced before and those were the exactly same symptoms I'm experiencing. One thing I didn't take note of during my observation earlier that day was the voltage would go up following my engine RPM (revolutions per-minute). The harder I rev the engine, the higher the voltage will go.

So with all the symptoms I've experienced, I was sure that its time to change my alternator. Since today is a Sunday, I was doubting that most workshops are opened but I was sure that the parts shop is still open until 3 pm. I did some reading on how to replace the alternator and after dropping my parents off, went to get a replacement alternator. This was my first time replacing the alternator on my own. If you are not confident, please let the workshop do it for you. As for my case, most workshop was closed and I'm trying to save a few ringgits on workmanship. :D

In this post, I would like to share with you, how to replace your alternator.

Tools Needed:

- Spanner (Size 8,12 and 14) *depending on car make and model. Here I'm referring to a 1999 Proton Satria GTI (engine code 4g93)

- Floor Jack

- Jack stand

- Gloves (optional)

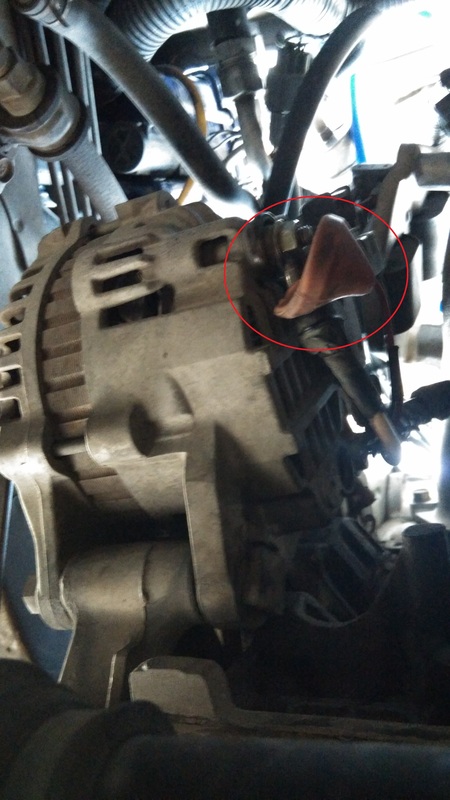

First things first, locate the position of the alternator.

So the it is, a DIY session for the weekend. A new rebuildable alternator for my ride, a new experience gained and roughly RM80 saved on the workmanship. :D

RSS Feed

RSS Feed